Blackbox 4 Edge

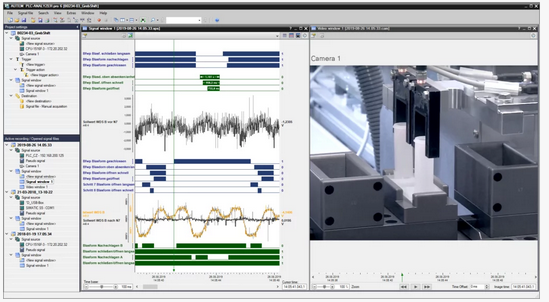

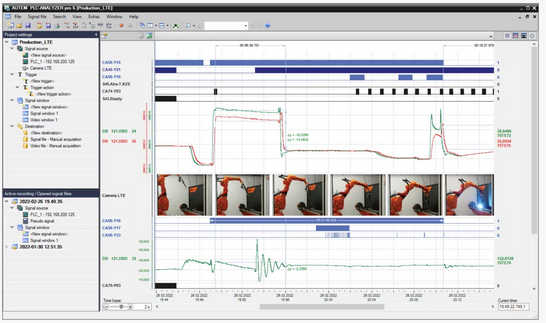

OverviewWith the BLACKBOX 4 Edge, AUTEM offers an ultra-compact special IPC for PLC process data recording, monitoring and remote maintenance of machines and systems based on the PLC-ANALYZER pro 6. The special IPC (fanless) can be easily integrated thanks to its small dimensions. The BLACKBOX 4 Edge can continuously record and archive process data over a very long period of time. In addition, video data can also be recorded synchronously with the PLC process data (Videotrack module). Fields of application

After power-on, the BLACKBOX 4 Edge automatically starts signal recording and then runs autonomously. |  Plant monitoring with the BLACKBOX 4 Edge The BLACKBOX 4 Edge is optimized for self-sufficient operation. An integrated watchdog ensures that the system automatically reboots in case of recording errors and continues recording. The operating status can be queried externally via potential-free contacts (“POWER-INDICATOR”, “LIFE-INDICATOR”, “ACTION-CONTACT”). Status messages can be transmitted automatically via SMS or e-mail. The autarkic operation allows the uninterrupted signal recording over several years. When the SSD memory capacity is reached, the oldest signal file is automatically deleted to create storage space for new signal data (FIFO). |

BLACKBOX 4 Edge: Ultra-compact system for PLC process data recording |  Seamless recording PLC + video with BLACKBOX 4 Edge |

For manufacturers and users of machines and plants this form of continuous recording is very advantageous. It is used in particular for troubleshooting and for documenting the operating behaviour and running of the plant. Maintenance, construction and quality assurance receive valuable information. The stored data also serve as incorruptible evidence in the investigation of causes and analysis of malfunctions and the clarification of warranty issues. Ideally, the machine manufacturer equips his system with BLACKBOX 4 Edge right from the factory in order to have immediate access to all important process data in the event of a fault. The BLACKBOX 4 Edge can also be used as a condition monitoring system for predictive maintenance. Communication with the PLC is via the paths supported by the PLC-ANALYZER pro 6, e.g. TCP/IP PROFINET, PROFIBUS, PG interface, Modbus+ or OPC UA. Process data can be acquired simultaneously from several PLCs. The optionally available AD_USB-Box® also allows the acquisition of external electrical measured values that are not available in the PLC. The BLACKBOX 4 Edge can be installed permanently or temporarily in the system. Locally or remotely, you can access the recorded data for further analysis at any time – even during ongoing recording. With the optional Virtual HMI module, which allows subsequent HMI visualization from recorded process data, operator errors – e.g. in a crane – can be analyzed extremely elegantly. This is a particular aid in clarifying plant accidents. | If required, a keyboard, mouse and display can be connected to the BLACKBOX 4 Edge. The multi connective system has connections for 2 x USB 3.0 and 2 x USB 2.0 as well as 2 x LAN port (Gigabit Ethernet). In addition, 2 x RS232 and 2 x DP display port are on board. Remote access via LAN connection from any PC is also particularly elegant. The necessary remote software and a suitable 3 m patch cable for direct connection are included in delivery. For remote access via the mobile network, the BLACKBOX 4 Edge can be equipped with an internal 4G LTE modem. The BLACKBOX 4 Edge requires 24 Volt DC. The included power supply unit also allows operation at 100~240 Volt AC. The system is delivered ready-to-use with the software license PLC-ANALYZER pro 6 for BLACKBOX 4 Edge (basic module + PLC driver). Bundles for different PLC systems are available.

|